The LulzBot TAZ 6 was officially released May 17, 2016. There have been many improvements to the quality, reliability, and performance. The electrical system experienced a massive overhaul compared to the TAZ 5.

The requirements for the electrical system in the TAZ 6 were the following:

- Repeatably pass FCC and CE Class B radiated emissions as well as compliance with all other EMC standards; Introduce proper grounding, masking, shielding, filtering, and low impedance return path schemes (test report)

- Significantly reduce the complexity of installation and assembly for the electronics and wiring; increase rate of production (manufacturing assembly documentation)

- Introduce ESD protection and significant immunity to ESD events

- Endstops are normally-closed to reduce EMI and to account for open-circuit failure modes

The EMC improvements made could only be done at the machine/wiring level due to the electronics being the same RAMBo board used in TAZ 5 to reduce NRE cost. Several TAZ 6 machines were tested and passed Class B, significantly increasing the sample size and confidence. On the TAZ 5 which lacks proper grounding, shielding, and filtering the PCB radiates quasi-peaks which are ~7dB above the Class B limit.

Figure 1: TAZ 6 Electrical Enclosure

Figure 2: TAZ 5’s Crammed, Messy Electrical Enclosure

Figure 3: LulzBot TAZ 6 (3 Meter) Test Setup for Radiated Emissions

Here is a video of a customer describing the EMC mitigation efforts:

The requirements for the firmware in the TAZ 6 were the following:

- Base the release off of upstream Marlin 1.0.2

- Add proper thermal runaway protection (commits: 94308924490e, d460d8461a9f, 18f22da21171, 073934caae06, 106d928ad9bb)

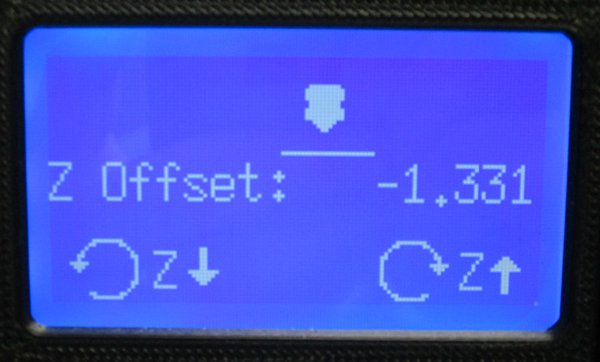

- New feature to allow the user to adjust the Z-Offset from the GLCD in real-time during the print and store the value to the MCU’s EEPROM when done (see Figure 4, later merged into mainline Marlin)

- Eliminate several bugs present in upstream

- Create pull requests and have them merged upstream for all significant bug fixes and improvements to the firmware (commits merged upstream)

- Create a makefile which can be used to build the firmware

- Create a manufacturing firmware checksum script and procedure

Figure 4: Adjusting the Z-Offset From the GLCD with Animations